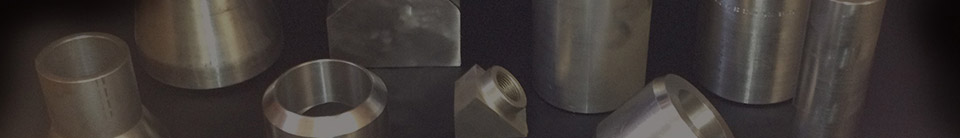

Custom Machined Pipe Fitting Coupling Fabrication

(Click on thumbnail to enlarge)

Since 1995, our team of experts at Universal Outlets, Inc. has been providing custom and specialty fittings for customers in a wide range of industries. Our tradition of quality was exemplified when a client in the petrochemical industry required custom built pipe fitting couplings. We employed carbon steel, and turned, bored, and drilled the raw material using our turning lathe. When completed, this configuration featured a one inch pipe size and came in at a weight of 3000 lbs. We were able to meet our customer’s exact specifications, fabricating this unit to tolerances of ±0.0015”. We delivered this unit to our U.S. customer with a turnaround time of just one week.

These couplings are available in configurations weighing anywhere from 150 to 6000 lbs., and in thread and socket weld or combination of socket weld & threaded options. To learn more about this project, please see the information below or contact us directly.

Custom Machined Pipe Fitting Coupling Fabrication Details

- Product Description

- Pipe Fitting Couplings

- Capabilities Applied/Processes

- Turning

Boring

Drilling

- Equipment Used to Manufacture Part

- Turning Lathe

- Overall Part Dimensions

- Pipe Size: 1"

Configuration: 3000lbs

- Tightest Tolerances

- ±0.0015"

- Material Used

- Carbon steel

- Additional Facts

- Comes in 150lbs-6000lbs configurations

Thread and Socket weld Configurations

- Industry for Use

- Petrochemical

- Volume

- 1 unit

- Delivery/Turnaround Time

- 1 Week

- Delivery Location

- United States

- Standards Met

- Customer Specifications

Print This Page

Print This Page Email This Page

Email This Page